ELECTRICAL PANEL UPGRADE

Upgrading your electrical panel can provide numerous benefits, including increased safety, improved electrical performance, additional capacity, compliance with electrical codes, increased property value, and potential energy savings. If you are experiencing electrical problems or your electrical panel is outdated, we recommend you call Peach Electric right away to assess your system and recommend the necessary upgrades to keep your home or business running safely and efficiently.

PANEL UPGRADE INFORMATION

Upgrading your electrical panel can provide numerous benefits, including increased safety, improved electrical performance, additional capacity, compliance with electrical codes, increased property value, and potential energy savings. If you are experiencing electrical problems or your electrical panel is outdated, we recommend you call Peach Electric right away to assess your system and recommend the necessary upgrades to keep your home or business running safely and efficiently.

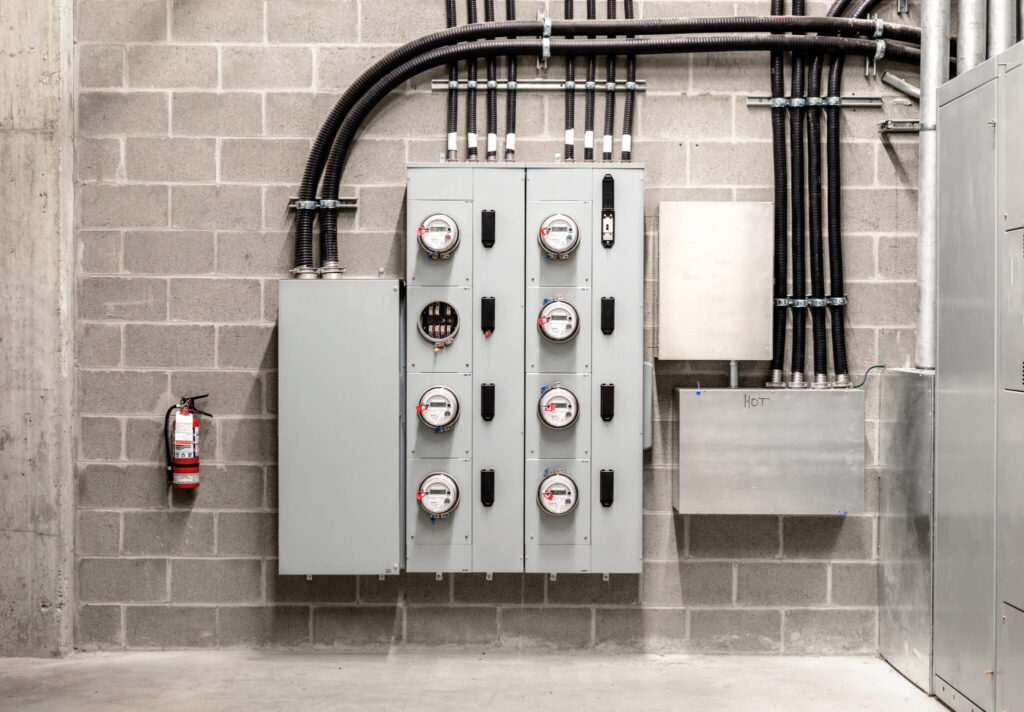

An electrical panel upgrade is a crucial service that ensures the safe and efficient operation of your electrical system. The electrical panel, also known as the breaker box, is the central hub that distributes power throughout your home or business. Over time, the electrical panel can become outdated or overloaded, which can lead to various electrical issues, including power surges, blown fuses, and even electrical fires. Upgrading your electrical panel is an effective way to prevent these problems and improve the overall performance of your electrical system.

The electrical panel upgrade service typically involves replacing the existing electrical panel with a new one that can handle the electrical load of your home or business. Peach Electric will assess your electrical system to determine the appropriate size and type of electrical panel that is required. We will then install the new panel and ensure that it meets all electrical codes and safety standards.

The benefits of upgrading panel:

Increased Safety – An outdated electrical panel can be a safety hazard, particularly if it is unable to handle the electrical load of your home or business. An electrical panel upgrade can reduce the risk of electrical fires, shocks, and other hazards.

Improved Electrical Performance – An electrical panel upgrade can improve the overall performance of your electrical system by providing a more reliable and efficient distribution of power.

Additional Capacity – A new electrical panel can provide additional capacity to accommodate future electrical needs, such as adding electrical vehicle chargers, solar, or expanding your business.

Compliance with Electrical Codes – Electrical panels must comply with local electrical codes and safety standards. An electrical panel upgrade can ensure that your electrical system is up to code and meets all safety requirements.

Increased Property Value – Upgrading your electrical panel can increase the value of your property, particularly if you are planning to sell your home or business.

Don’t overlook the importance of an electrical panel upgrade. By enhancing the safety, performance, and value of your electrical system, this vital service is essential for any home or business. If you suspect that your electrical panel is outdated or struggling to handle your electrical load, don’t hesitate. Contact Peach Electric today to assess your system and provide the necessary upgrades to keep your property running safely and efficiently.

Hazardous Situations:

Overloading: Older electrical panels may not be equipped to handle the increased electrical demand of modern homes and appliances. Overloading can cause the panel to overheat and potentially lead to electrical fires.

Insufficient circuit protection: Older panels may not have enough circuit breakers or fuses to adequately protect the electrical circuits in your home. This can cause electrical circuits to overload and potentially start fires.

Deterioration: Electrical panels can deteriorate over time due to wear and tear, corrosion, and exposure to the elements. Deterioration can cause the electrical connections within the panel to become loose or damaged, potentially leading to shorts, electrical arcing, and fires.

Obsolete technology: Older electrical panels may contain outdated technology and parts that are no longer available or approved for use. This can compromise the safety and reliability of the electrical panel and the entire electrical system.

Lack of safety features: Many older electrical panels lack modern safety features such as ground fault circuit interrupters (GFCIs) and arc fault circuit interrupters (AFCIs) that are designed to detect and prevent electrical hazards.

Old electrical panels can be dangerous due to their inability to handle modern electrical demands, insufficient circuit protection, deterioration, outdated technology, and lack of modern safety features. If you suspect that your electrical panel is outdated, it’s essential to contact Peach Electric to assess your system and recommend the necessary upgrades to keep your home or business safe.

Dangerous Electrical Panel Manufacturers:

- Federal Pacific Electric (FPE): FPE is a company that manufactured millions of circuit breaker panels that have been associated with several safety concerns, including faulty circuit breakers, poor design, and lack of safety certifications.

- Faulty circuit breakers: The circuit breakers in FPE panels have been known to fail to trip during an overload or short circuit, allowing too much electrical current to flow through the panel and potentially leading to electrical fires.

- Poor design: FPE panels were designed and manufactured with several technical and design flaws that increase the risk of electrical hazards.

- Age-related issues: Over time, FPE panels can deteriorate due to wear and tear, corrosion, and exposure to the elements, potentially leading to electrical arcing, shorts, and fires.

- Lack of safety certifications: FPE panels were not subjected to rigorous testing and certification processes by independent testing organizations, such as Underwriters Laboratories (UL), which is the main organization that certifies electrical products for safety.

- No longer manufactured: FPE panels have not been manufactured for several decades, meaning that replacement parts and components are often hard to find and no longer manufactured.

- Zinsco: Zinsco panels were manufactured between the 1940s and 1970s and have been known to have issues with overheating, melting, and failing to trip during overloads or short circuits.

- Overheating and melting: Zinsco panels have been known to overheat and melt due to poor design and manufacturing, causing significant safety hazards.

- Inability to trip during overloads: Zinsco circuit breakers have been known to fail to trip during an overload or short circuit, leading to overheating and potentially starting electrical fires.

- Lack of replacement parts: Zinsco panels have been out of production for several decades, and replacement parts are often challenging to find. As a result, electricians may have to replace the entire panel, which can be costly.

- Age-related issues: Zinsco panels can deteriorate over time, leading to electrical arcing, shorts, and fires. In addition, the panels may not meet current safety standards or electrical codes, posing safety risks.

- Lack of safety certifications: Zinsco panels were not tested and certified by independent organizations, such as Underwriters Laboratories (UL), which is the primary organization that certifies electrical products for safety.

- Challenger: Challenger panels were manufactured in the 1980s and have been known to have issues with circuit breakers failing to trip during overloads or short circuits, potentially leading to electrical fires.

- Pushmatic: Pushmatic panels were manufactured in the 1950s and 1980s and have been known to have issues with circuit breakers failing to trip during overloads or short circuits.

- Bulldog: Bulldog panels were manufactured in the 1950s and 1960s and have been known to have issues with circuit breakers failing to trip during overloads or short circuits, potentially leading to electrical fires.